Duroplastic™

Fire-extinguishing fiberglass

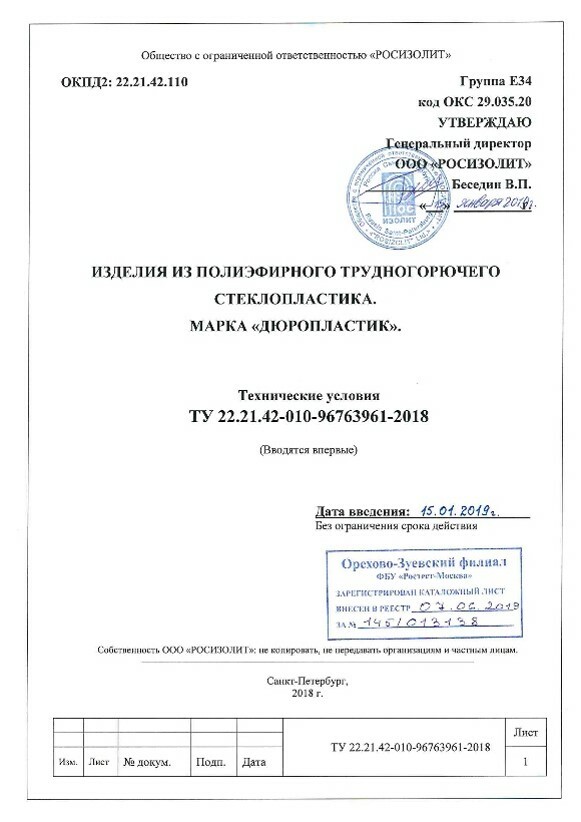

TS 22.21.42-010-96763961-2018

Что может заменить Дюропластик™

Advantages of Duroplastic™

Advantages of Duroplastic™

100%

import substitution

2 weeks

shipping period

60 t/month output

> 1000 material properties options

Duroplastic™ will help you

Duroplastic™ will help you

It is assumed that Duroplastic® will be used:

- as a structural material in the construction of new modern cars;

- as an electrical insulating material replacing traditional composite materials in power equipment;

- as an import-substituting material

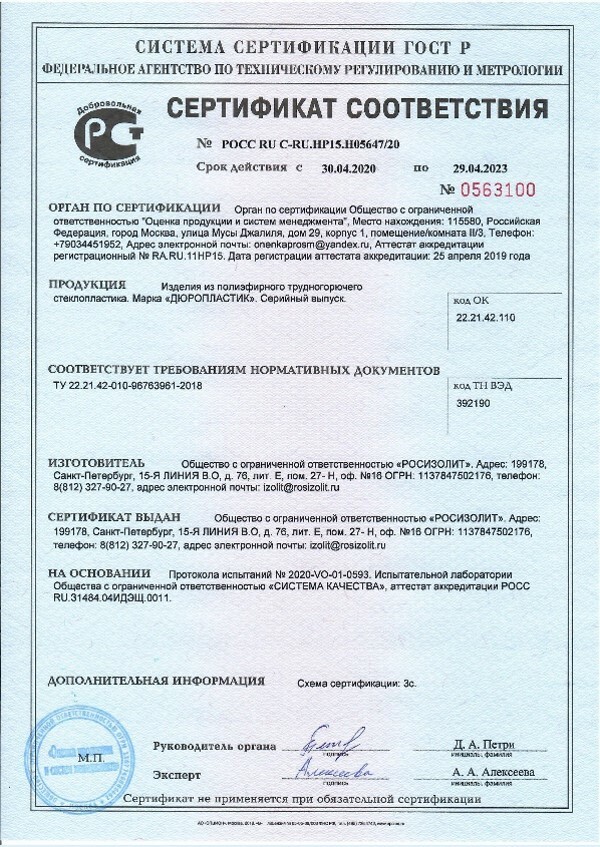

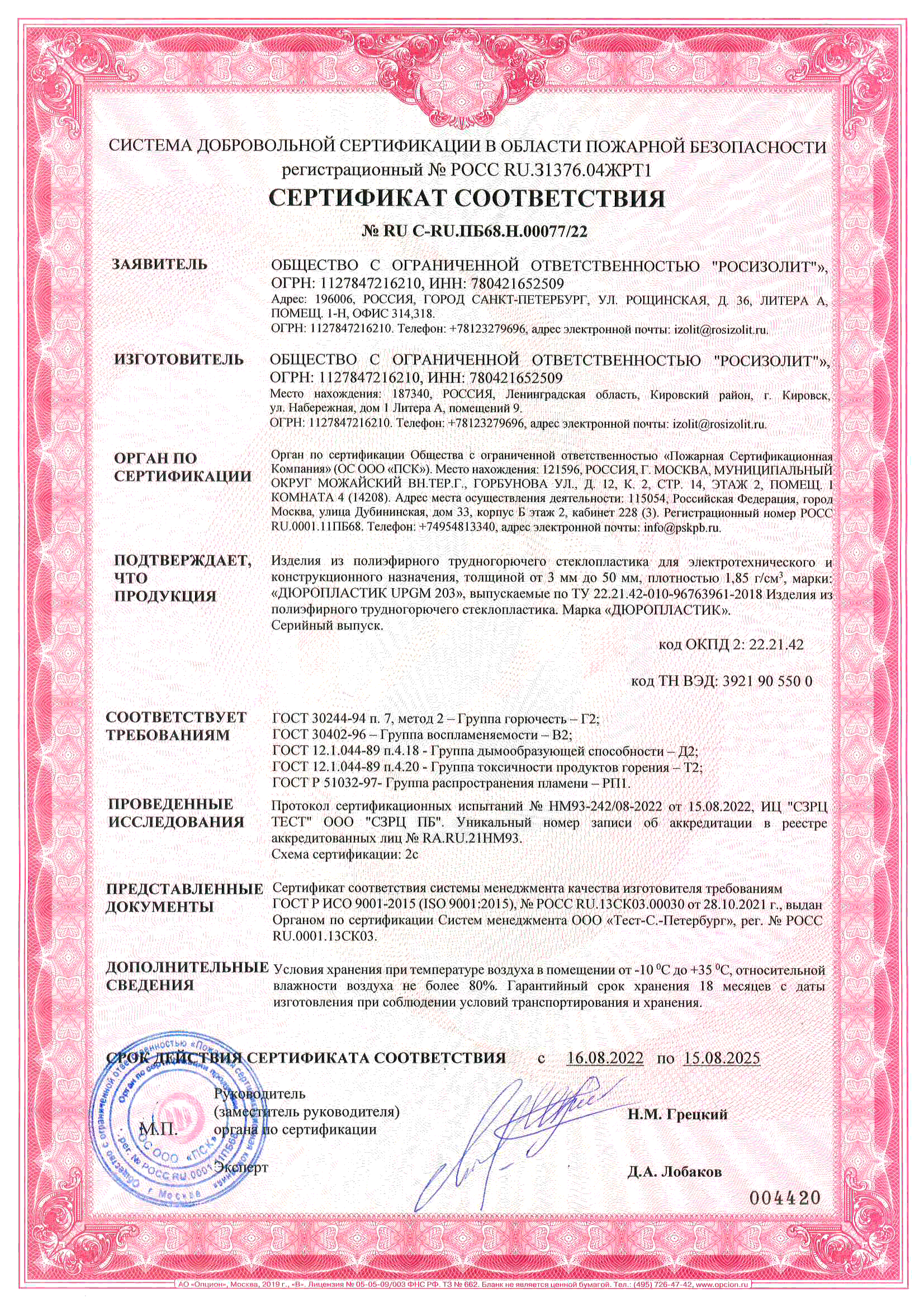

The reliability of Duroplastic has been confirmed by experts.

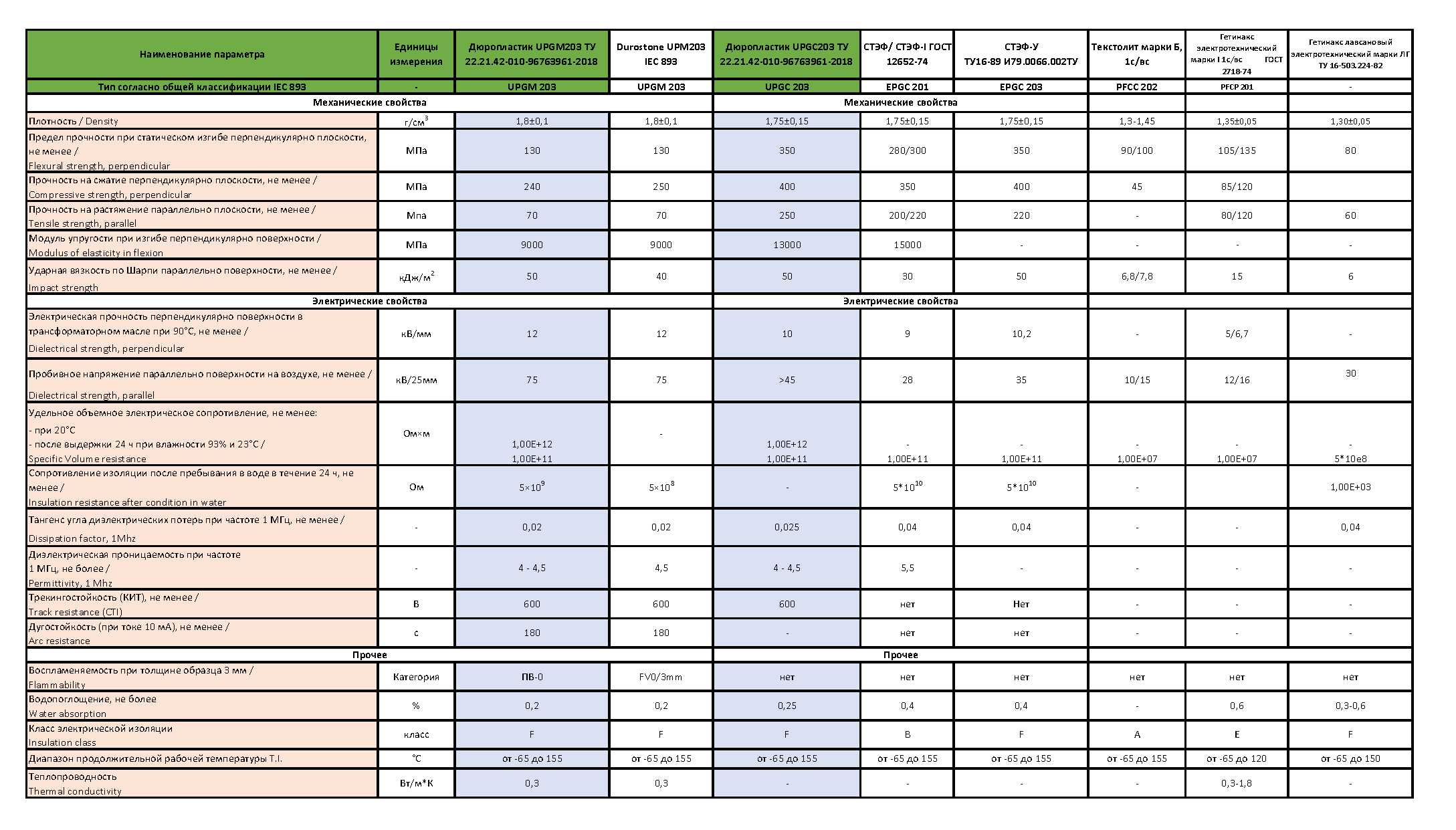

Characteristics of Duroplastic™

Characteristics of Duroplastic™

Characteristics of Duroplastic

High arc resistance and tracking resistance

Обладает низким

влагопоглощением

Duroplastic™ is produced in St. Petersburg, Russian Federation

Duroplastic™ is produced in St. Petersburg, Russian Federation

DuroplasticTM complies with the Russian and international standards:

DuroplasticTM complies with the Russian and international standards:

Pattern GPO3 according to standard NEMA LI.1

- Типы UPGM203 и UPGС203 согласно стандарту IEC EN 60893

Acquire free full technical specifications for Duroplastic™and expert’s advice:

Acquire free full technical specifications for Duroplastic™and expert’s advice:

- Technical parameters

- Dimensions

- Color

- Test results

By filling in the form, you agree to Privacy Policy

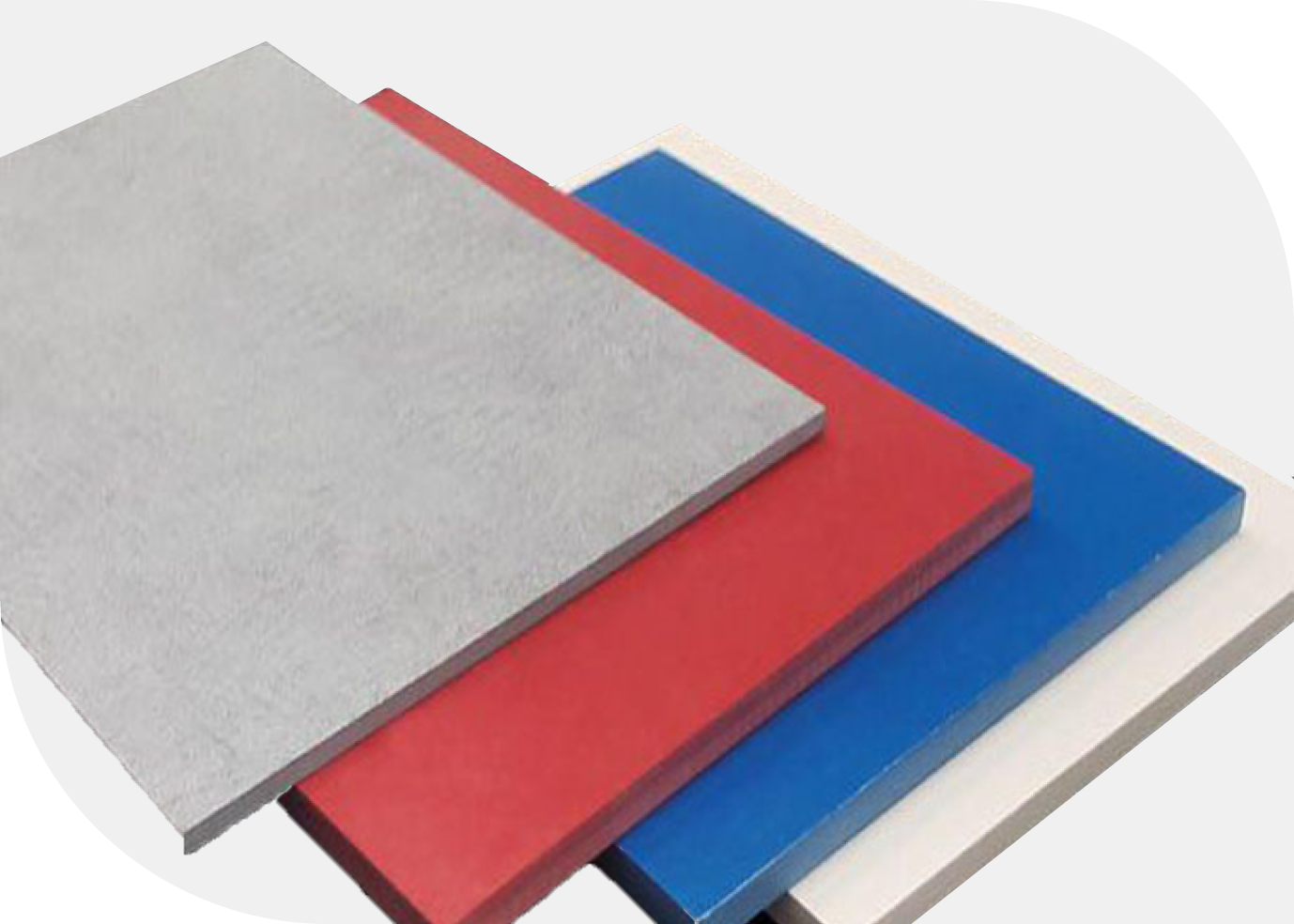

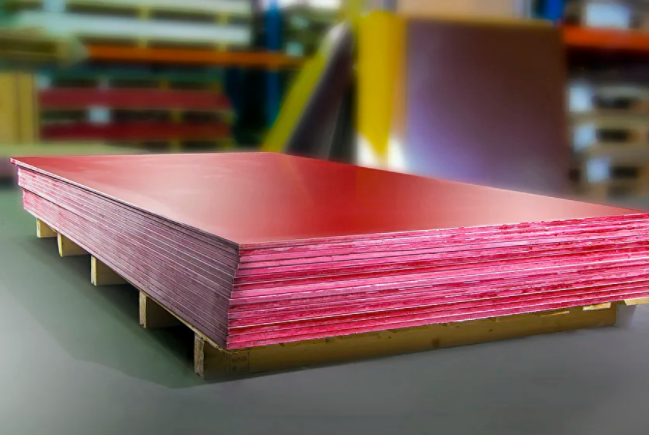

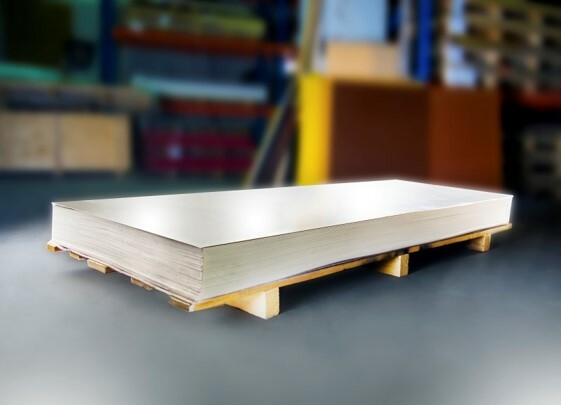

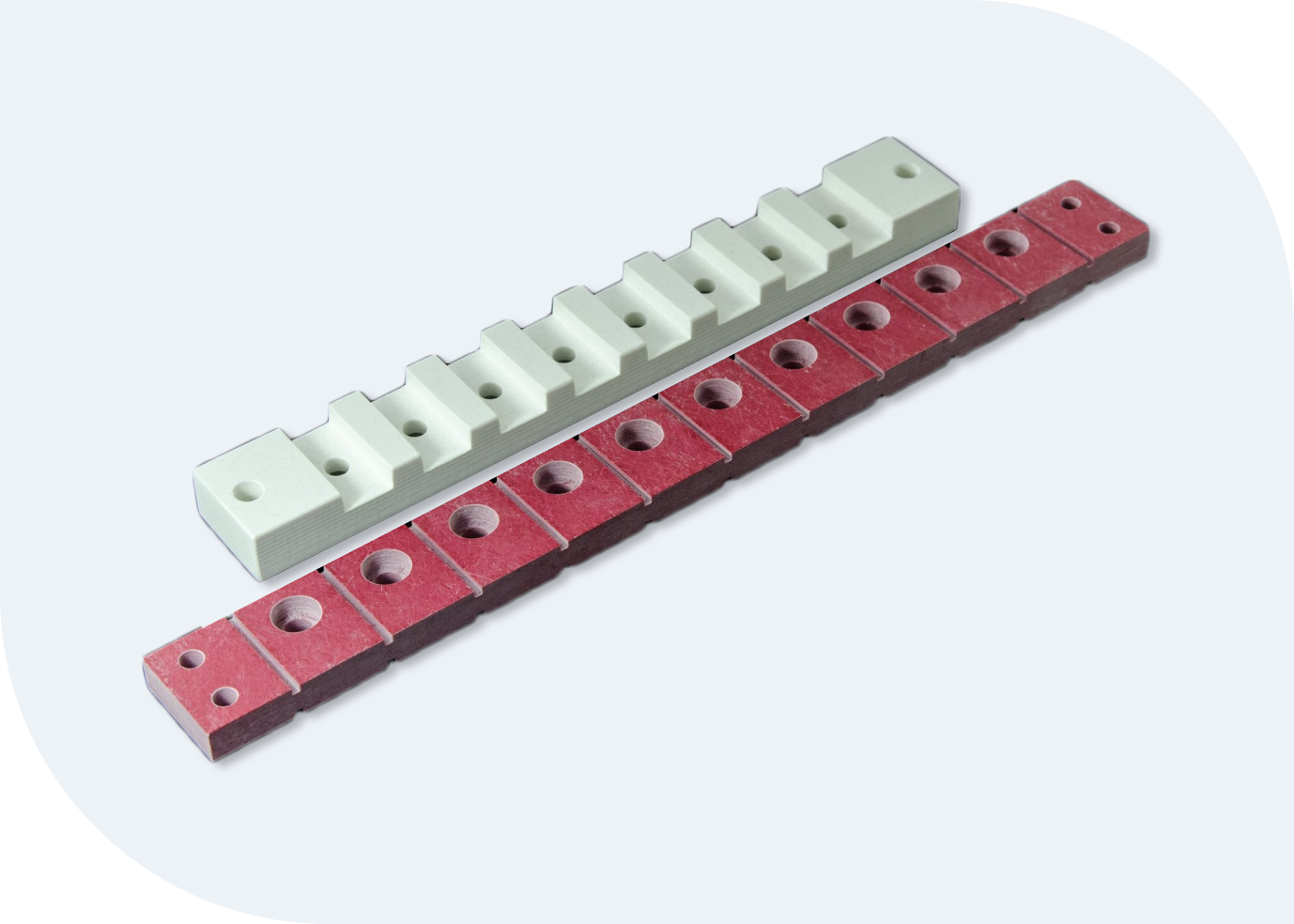

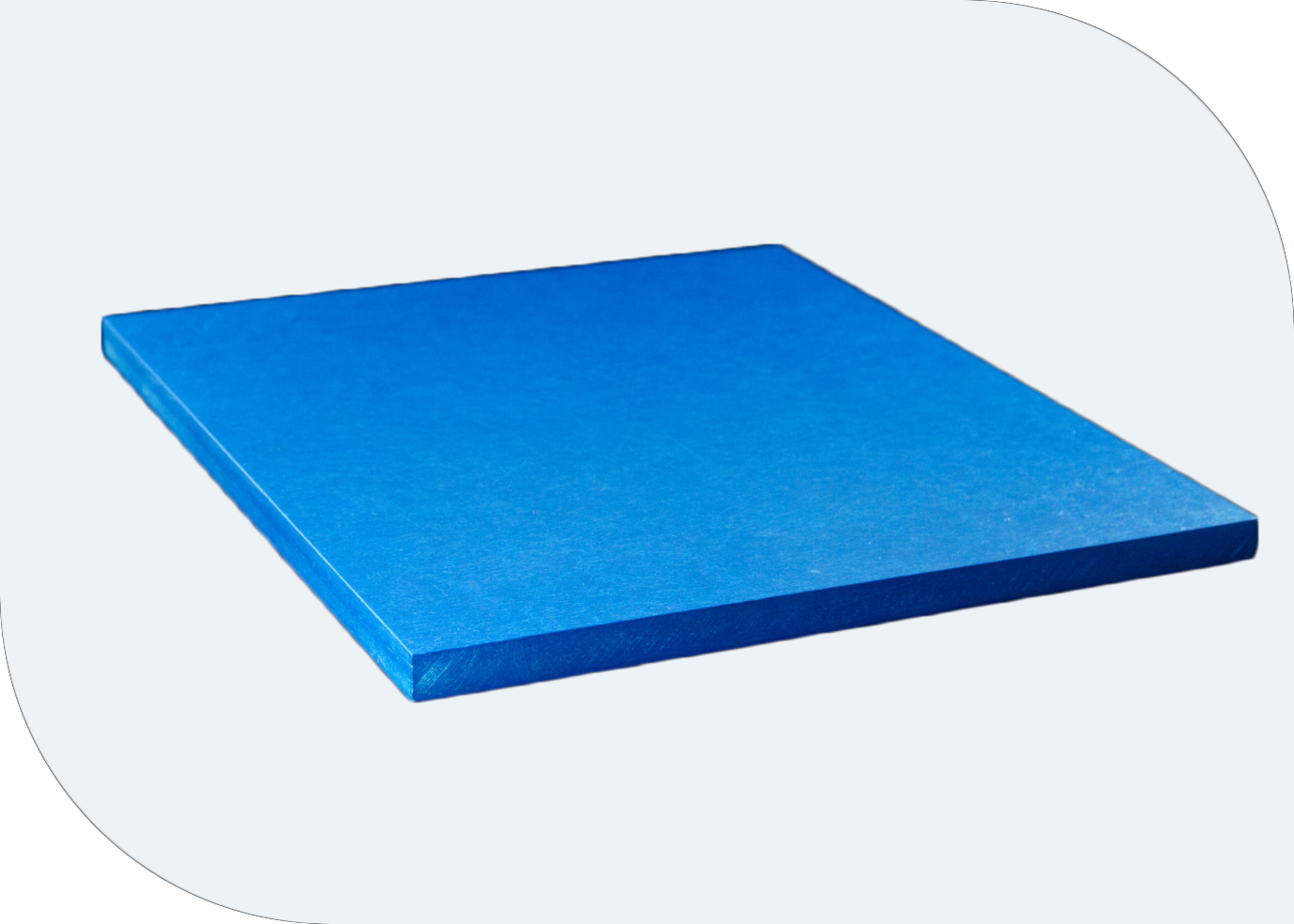

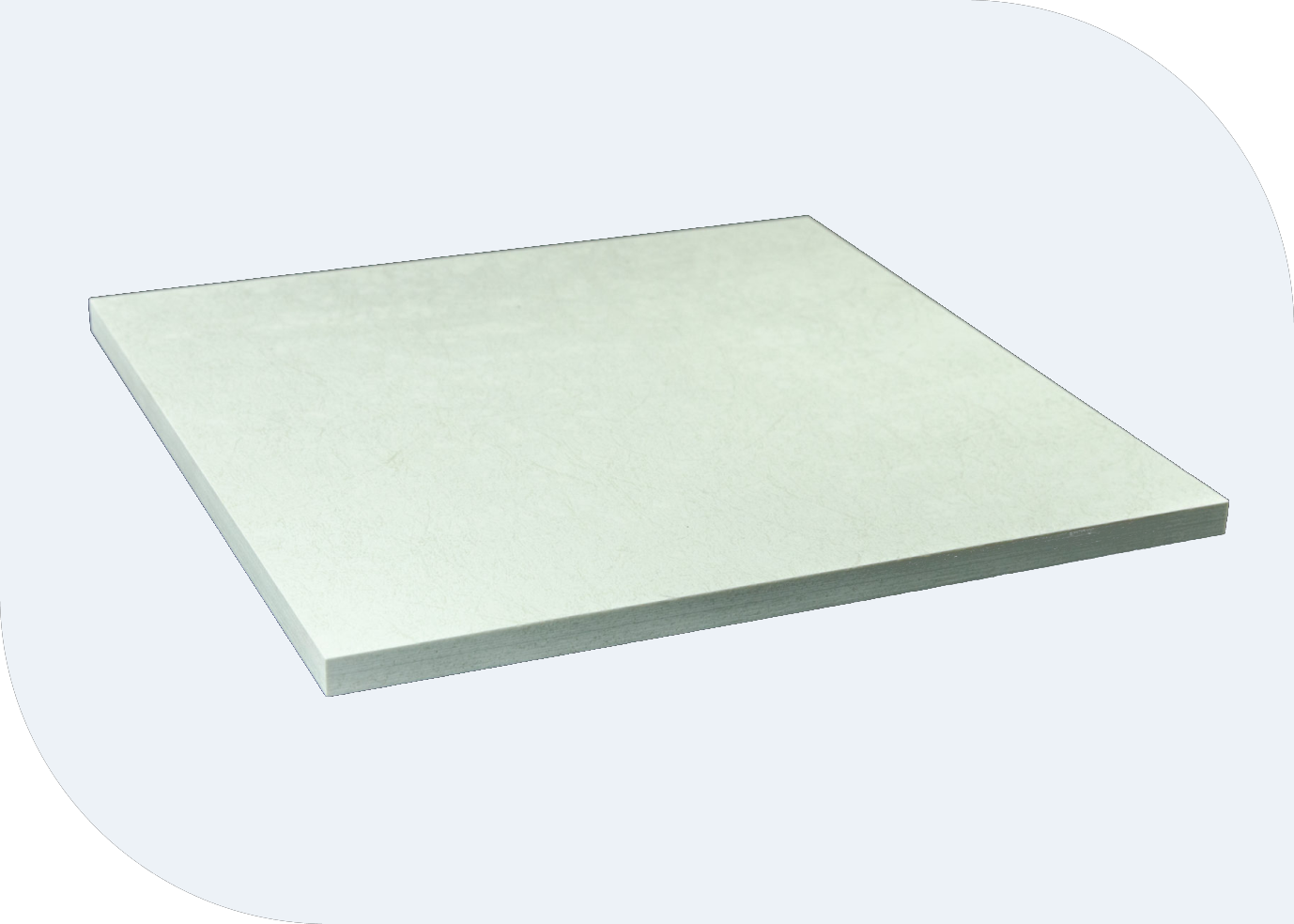

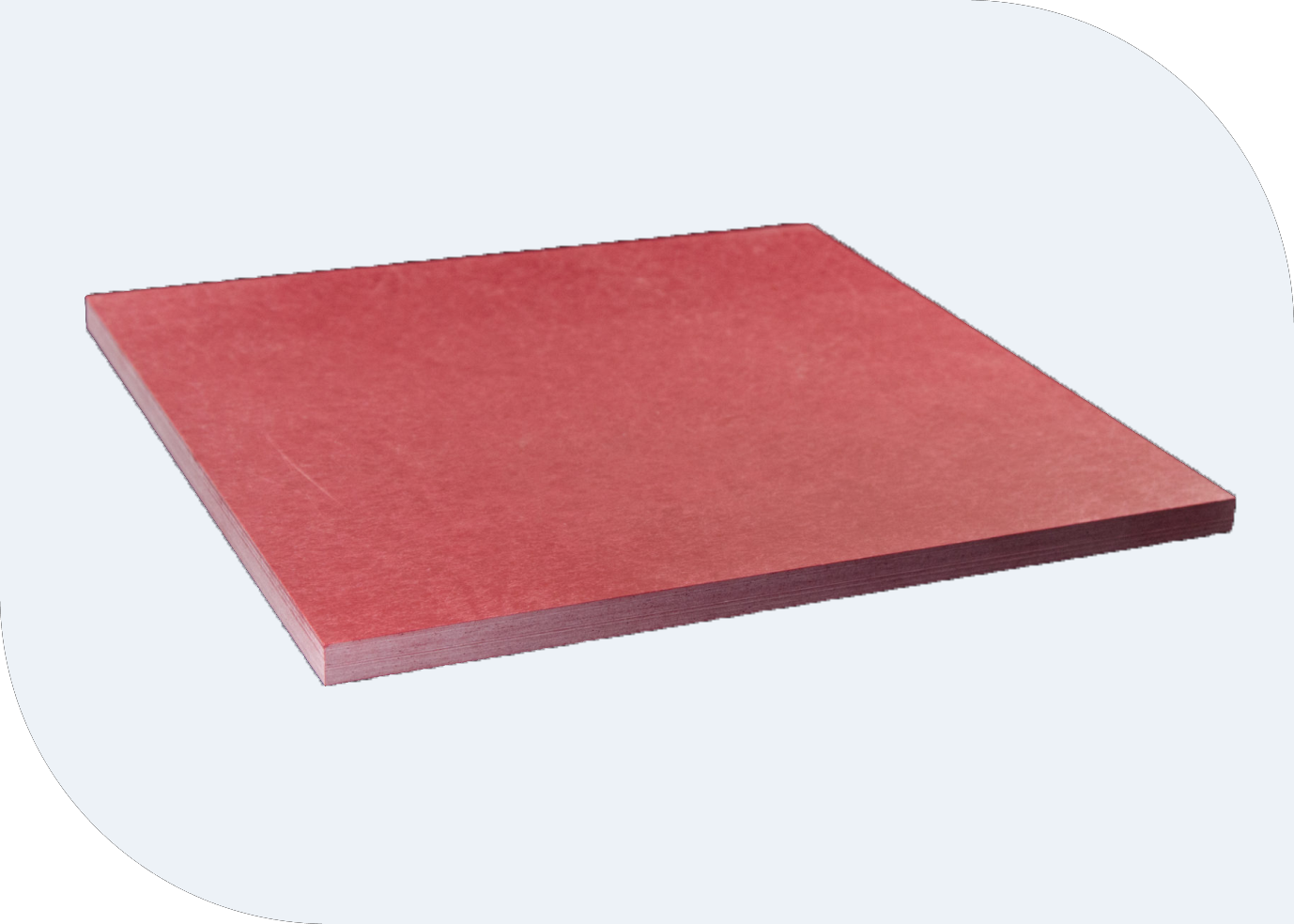

Types of DuroplasticTM

Types of DuroplasticTM

As sheets

Standard color: white, red.

Any thickness, size, and color according to RAL

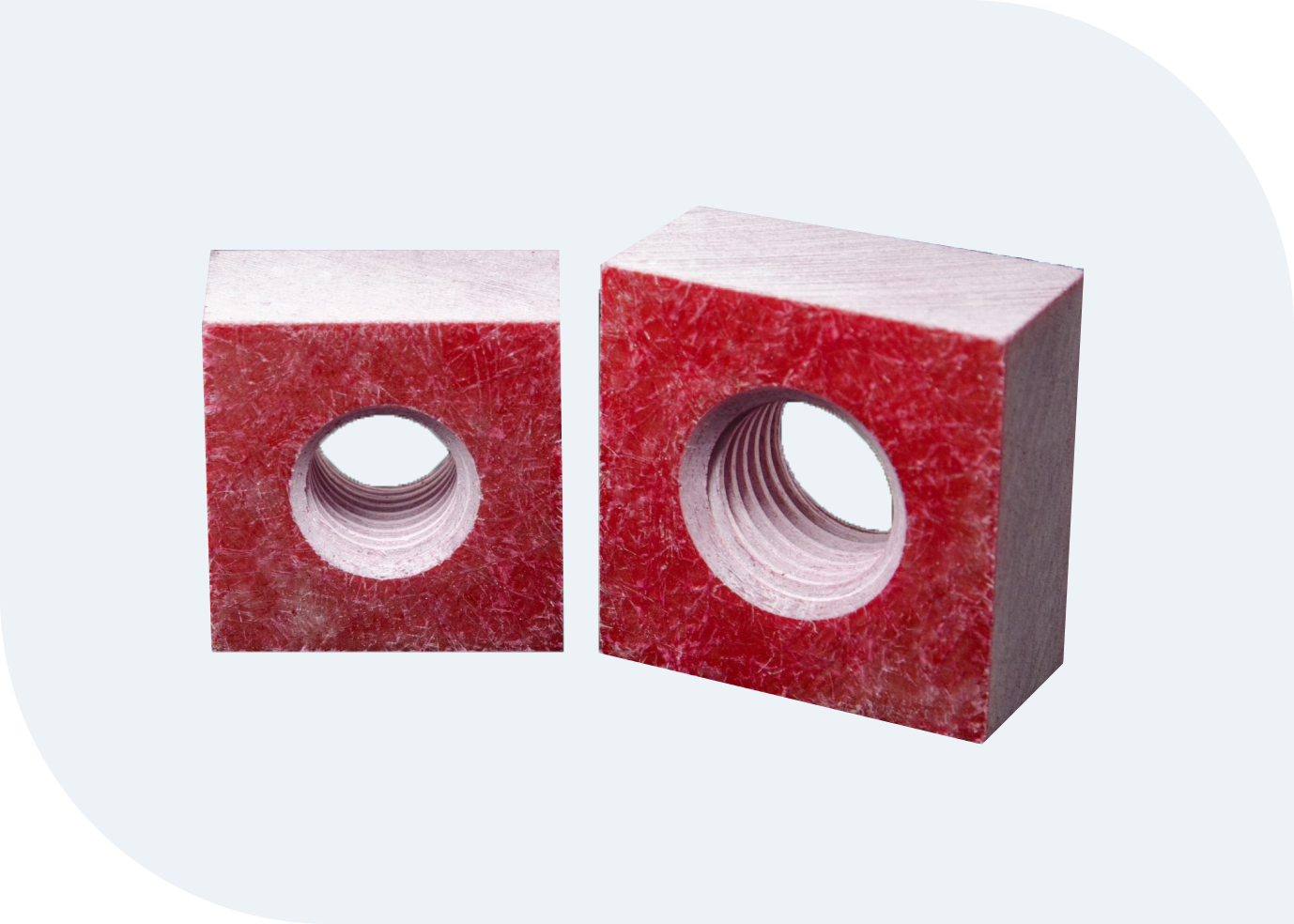

As molded 3D products

As machined components

The quality of Duroplastic™ fiberglass is controlled at our proprietary testing laboratory of the research and development center

Applications

Applications

For electrical insulation:

- In electrical apparatus and power equipment as sheets or finished components – as electrical insulating material

- In chemical equipment and industrial processes in electrolyzers, galvanic lines – as electrical insulating chemically resistant material

- In marine equipment, electrical equipment when operating in conditions of high humidity, low temperatures, risk of “dew point” – as materials for housings, panels, partitions, casings

Как конструкционный и отделочный материал:

- For finishing of industrial premises – as a fire-extinguishing and non-conductive material

- For interior finishing elements and partitions of passenger electric transport and cars

- For exterior and interior finishing of vans and refrigerators, cladding of vehicle bodies

- For finishing of external house and industrial doors

- For table coatings and chemical processing equipment

- For partitions and cubicles of public bathrooms – as a self-supported finishing and structural material

For wide application range

- In electrical equipment

- In dry type transformers

- In electrical machines components

- In arc-extinguishing chambers of power circuit breakers

- In electrical apparatus housings

- In insulating housing elements of wind generators

- In housings for power electric switchboards

- In control panels and cabinets for automatic circuit breakers and fuses

Examples of products made of Duroplastic™

Examples of products made of Duroplastic™

Manufacturing technology

Manufacturing technology

RTM manufacturing technology

Compactness of production and less costs in small-batch production

Simple production line changeover

The use of raw material produced in Russia

Output – up to 60 t/month

Production time is 2-3 weeks

- RTM manufacturing technologyfor high-solid, fire-extinguishing plastic

- Компактность производства и меньшие затраты при мелкосерийном производствеreduces the prime cost of products and final price for the consumer

- Простая переналадка производственной линииcapability to produce products of various shapes, dimensions, with a given set of specifications without substantial investments

- Работа на российском сырье100% импортозамещение

- Производительность 60 тн./мес.allows us to provide products for mass serial production

- Production time is 2-3 weeksinstead of 4–6 weeks of production using the classical technology

Certificates

Certificates

Our clients

Our clients

Остались вопросы?